FRILO & CARBOrefit® | The calculation with carbon concrete pays off

Since sustainability and resource efficiency will significantly shape the future of construction, practical solutions that take climate protection into account are increasingly in demand. With CARBOrefit®, the German service provider CARBOCON GmbH has developed an innovative process that enables renovation and reinforcement with carbon concrete. To increase the practical application of resource-efficient and durable carbon concrete reinforcements in planning and design, the CARBOrefit® process has now been integrated into the FRILO software.

More and more reinforced concrete structures in Germany are getting on in years and a crucial decision must be taken. Corrosion damage and load-bearing problems raise the question that should be considered for every single case: Does the building necessarily have to be demolished or is restoration and thus preservation also an option? From an ecological, social and economical point of view, the preservation and continued use of existing buildings is highly recommended, because the longer buildings can be used, the fewer new constructions are required. The erection of a new building involves more costs and a higher depletion of resources – in particular, the energy-intensive production of cement releases large amounts of CO2. At the same time, the restoration or reinforcement of buildings that have deficiencies or are to be converted can also bring about the desired result for the intended use – as the example of the Hyparschale in Magdeburg impressively demonstrates. Therefore, the preservation of as many existing buildings as possible plays a key role in achieving the climate goals. But this will require efficient and economical solutions for the renovation and reinforcement of existing structures.

What can carbon concrete do?

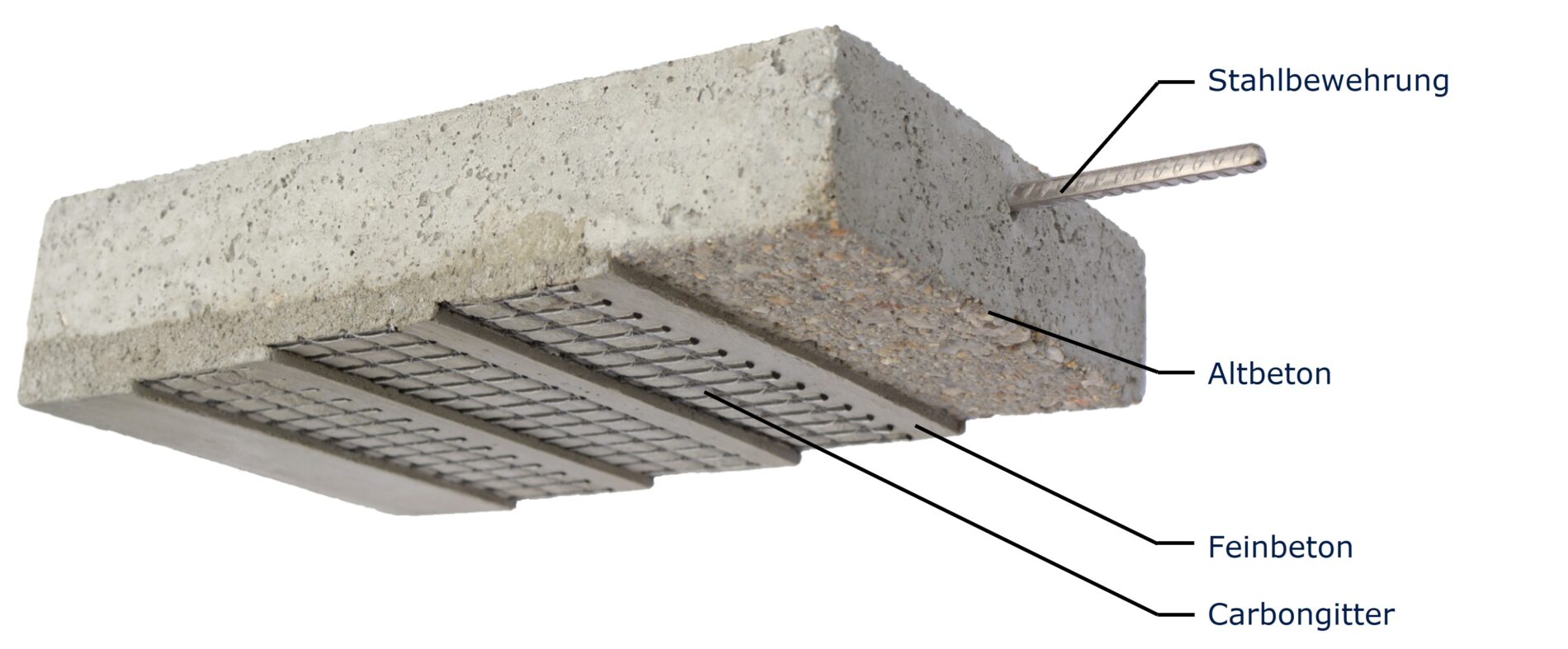

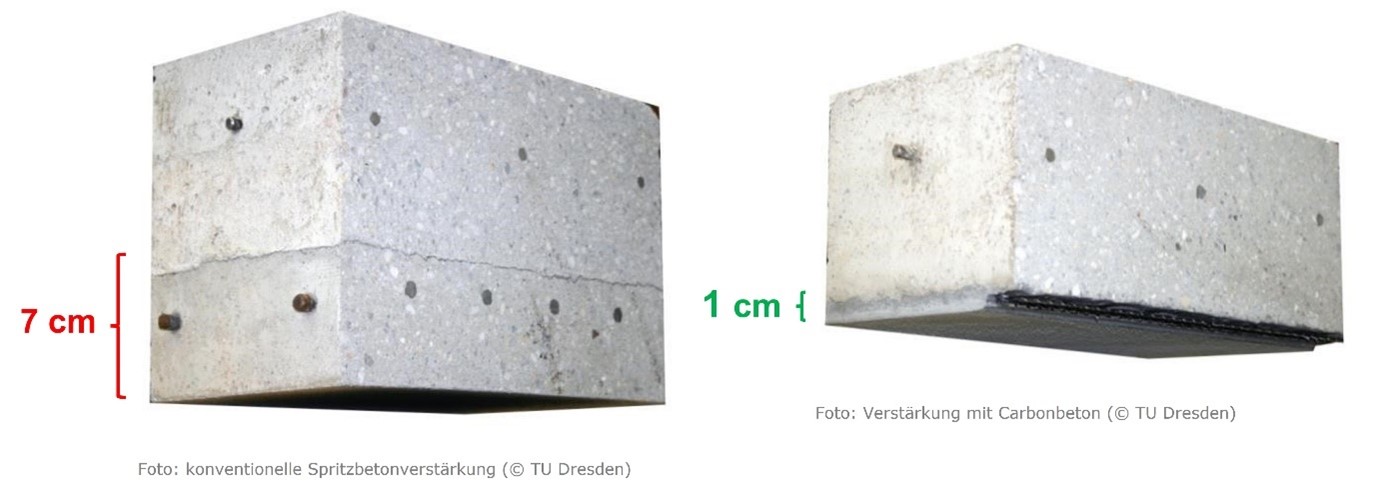

The insight that retrofitting buildings pays off for the climate balance is not new. Various restoration methods have been used in reinforced concrete construction for decades: cast-in-place concrete complements, reinforced shotcrete, bonded lamella reinforcement made of steel or fibre-reinforced composites, as well as external prestressing. Carbon concrete is an innovative building material that has been available to the construction industry for some time now and permits particularly environmentally friendly renovation and reinforcement. Carbon concrete is composed of impregnated carbon grids and fine concrete and is applied to the tension-loaded side of the reinforced concrete component to strengthen the bending load-bearing capacity. The carbon grids are extremely fine-meshed and at the same time very powerful – they have a significantly higher tensile strength than common reinforcing steel (see Table 1). Moreover, carbon reinforcement is corrosion-resistant and, therefore, the thickness of the concrete cover can be considerably reduced in comparison to steel reinforcement. The load-bearing capacity of the component can be significantly increased with a supplementary layer of only a few millimetres. The component’s self-weight increases only slightly through this.

As a consequence, major resource and CO2 savings are already achieved by the material properties and the associated reduced material requirements. Moreover, carbon concrete exhibits only narrow cracks due to the fine-meshed and near-surface carbon grid and is denser and more durable than reinforced concrete. In addition to reinforcing the structure, it also provides for a considerably longer service life and significantly increased durability of the building. The good bonding behaviour in combination with reinforced concrete should be emphasised. Due to the two-dimensional load transfer between the existing structure and carbon concrete, no additional dowelling is required. This offers a significant advantage when upgrading an existing structure with tendons, for instance. The possibility of preserving the contour of the existing building component is also a major benefit – carbon concrete is therefore also ideal for the preservation of listed buildings.

CARBOrefit® controls the use of carbon concrete

Since 2014, a National Technical Approval (abZ) has been available for reinforcement with carbon concrete. The CARBOrefit® process, which is being further developed and promoted by CARBOCON GmbH on behalf of a consortium of eleven partner companies, is based on the National Technical Approval (abZ) and the General Construction Technique Permit (aBG) CARBOrefit® Z-31.10-182 – issued by the German Center of Competence in Civil Engineering (DIBt). The continuous further development of this approval and the provision of numerous planning aids make it increasingly easy for design engineers to actually use carbon concrete in construction practice.

The innovative composite material consists of CARBOrefit® fine concrete and impregnated CARBOrefit® carbon grids. The geometry of the grids can be adapted to the requirements of a specific project and the designing engineer can choose between two types of scrims with different tensile and bond strengths. The reinforcement can be applied with up to four layers of carbon scrim or for a maximum design tensile force of 430 kN/m in the entire carbon reinforcement. The carbon reinforcement may only be exposed to tensile stresses. However, it can also be applied to the compression-loaded component side where it helps improving durability. In addition, the CARBOrefit® process is only allowed in component areas where no shear force reinforcement is required by calculation. The reinforcement must not be taken into account for the shear resistance. The shear joint verification ensures that the existing cross-section and the reinforcement interact.

The integration of CARBOrefit® in the FRILO software

The design of the CARBOrefit® carbon concrete reinforcement is inspired by the design of shotcrete reinforcements. Until now, however, there has been a lack of software-supported planning and design to support structural engineers in handling carbon concrete reinforcements. To establish CARBOrefit® as a recognised standard process for the renovation, reinforcement and restoration of reinforced concrete structures and thus save numerous further existing buildings from demolition, FRILO and CARBOCON have jointly developed a design tool and launched it on the market. Even if the module does not yet include all the verifications to be performed, the integration of the process into the FRILO program Reinforced Concrete Design B2 represents a first important step in the digitalisation of the planning and design process. For the cases and problems not yet covered, the CARBOrefit® planner folder provides specific and helpful content free of charge to support a complete verification process.

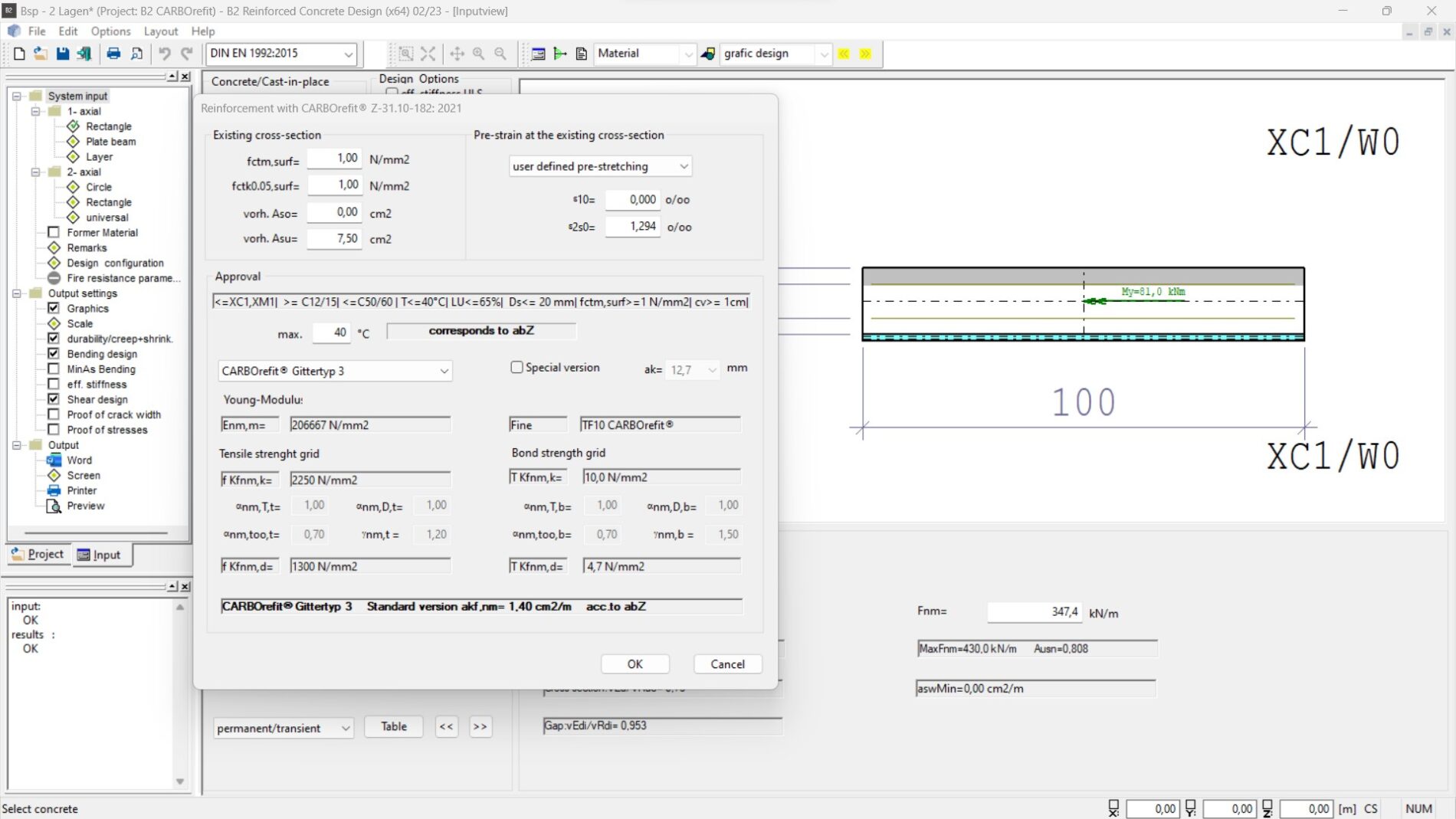

In the program Reinforced Concrete Design B2, the design of carbon-reinforced concrete cross-sections is currently possible based on the current DIBT approval (abZ/aBG). The possible applications of the CARBOrefit® process are precisely defined. The same applies to the cross-section of the existing structure and the ambient conditions. Thus, the approval is only valid for dry interior components made of reinforced concrete at a maximum relative humidity of 65 % and a maximum temperature of 40 °C. The existing structure must consist of standard concrete (strength class ≤ C50/60) and steel tensile reinforcement with diameters not exceeding 20 mm. There are also requirements concerning the concrete cover and the surface tensile strength of the existing concrete structure. In practice, projects quickly go beyond the application options defined by the approval, however. Therefore, carbon concrete reinforcements often require approval on a case-by-case basis.

The verification process in B2

The B2 program checks the aforementioned requirements of the approval. Based on the expertise of CARBOCON GmbH, a design going beyond the approval is also possible in the program. The output in the program makes deviations clearly visible and is accompanied by corresponding notes and recommendations for modifying the partial safety factors. B2 determines the number of required carbon grid layers from the effects of the axial force and bending acting on the defined cross-section. In addition, if shear force applies the program performs the shear verification for the existing cross-section and for the joint between the existing old concrete and the carbon concrete to apply. Based on the approval, uniaxially loaded rectangular cross-sections with or without a cast-in-place concrete complement on top are possible. A practical enhancement of the reinforcement tool is the database of historical materials available in B2, which determines Eurocode-based parameters for concretes and steels from 1916 onwards. In addition, a completely free definition of the old concrete and reinforcing steel is possible.

Step-by-step design

First, define the existing cross-section. In this process, you can enter the concrete quality, the type of reinforcement and the steel grade as well as the geometry. Then, enter the effects of actions that will act on the component after reinforcement. In the dialog for durability, you can define the diameters of the existing steel reinforcement and set the specifications for environmental conditions such as exposure classes or humidity. After that, you can determine the reinforcement with CARBOrefit®. For this purpose, the properties of the existing structure that are relevant to the design are first queried. Subsequently, certain criteria for reinforcing with CARBOrefit® are checked in accordance with the National Technical Approval (abZ). You can select the grid among the approved types and consider a special design. Based on the stored properties of the CARBOrefit® reinforcement, the central design results are determined and displayed: the required carbon reinforcement, the existing carbon reinforcement per layer, the number of grid layers as well as the utilisation. In addition, the shear force loading of the existing cross-section and the joint between the old concrete and the carbon concrete are shown if shear load applies. The final output compiles the entire design from the data entry to the results.