Weld Design

ST5

The ST5 program is used for the design of fillet welds for any type of rolled standard section. Therefore, it is suitable for the verification of a classical corbel connection.

Discover now more programs from the section Steel!

SHOW MOREMaterial

- Structural steel: S235, S275, S355, S450

- Annealed steel (S275N – S460N)

- Thermo-steel (S275M – S460M)

- Weathering steel (S235W – S355W)

- High-temperature steel (S460Q – S460QL1)

- Hollow section, hot-finished (S235H – S355H)

- Hollow section, hot-finished, fine-grain (S275NH – S460NH)

- User-defined steel

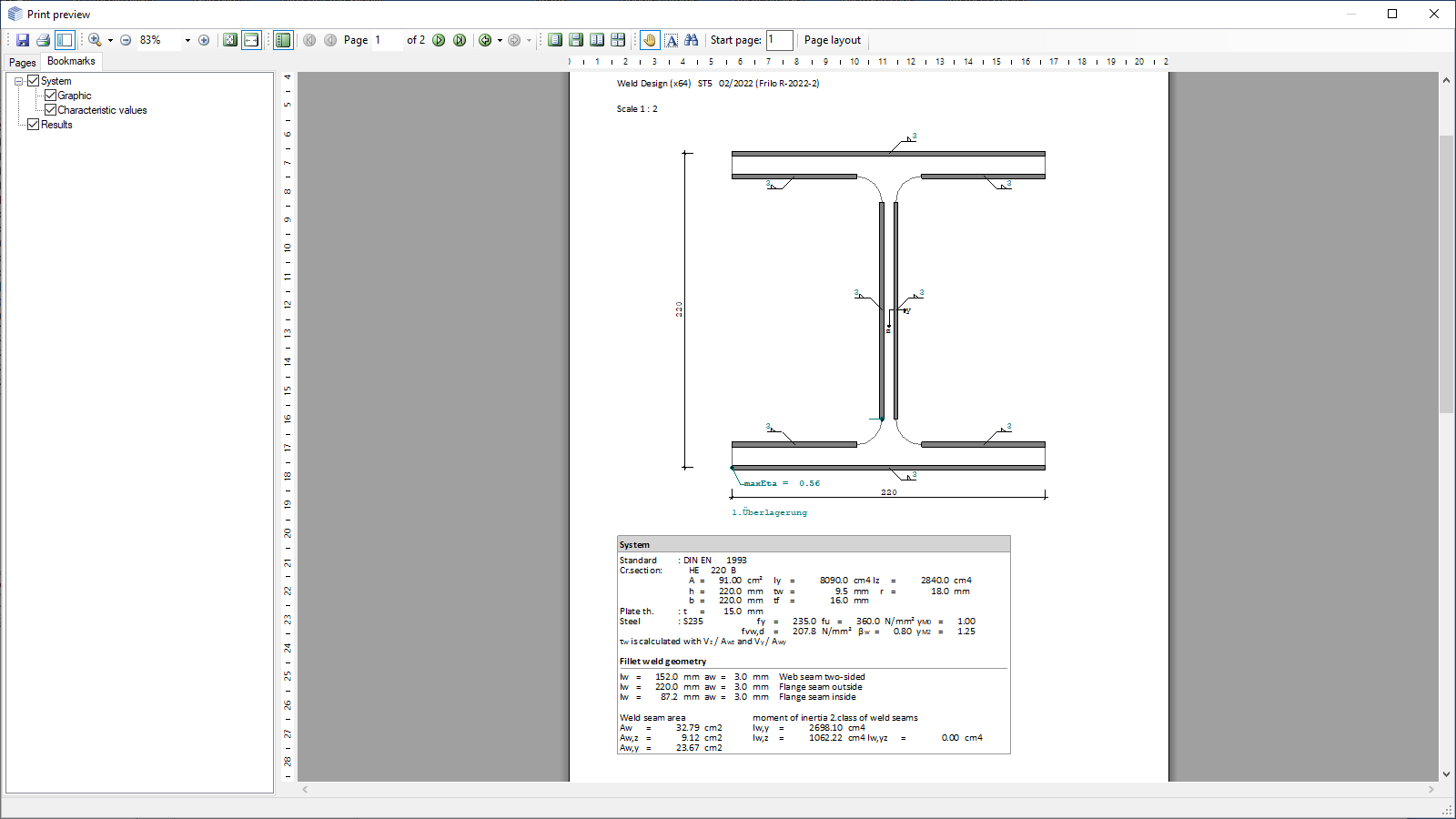

Structural system

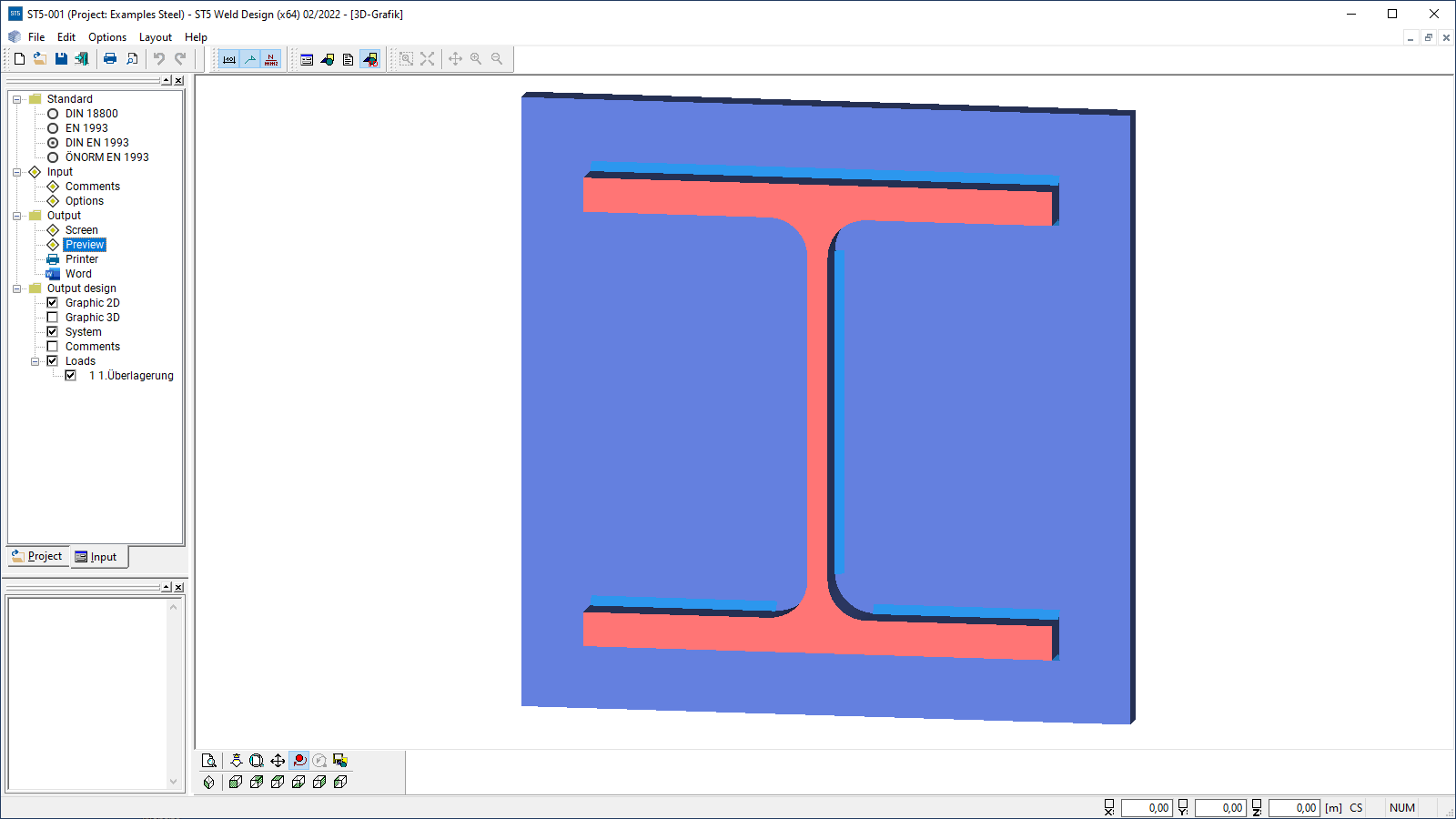

Cross-sections:

- I-sections, half I-sections, U-sections, T-sections, square, rectangular and circular hollow sections, angular, round, square and flat steel sections as standard shapes

- Double T-sections, unequal double T-sections, rectangular and circular hollow sections, rectangular solid sections, U-sections, round steel sections, angular steel sections with equal and unequal legs as user-defined shapes

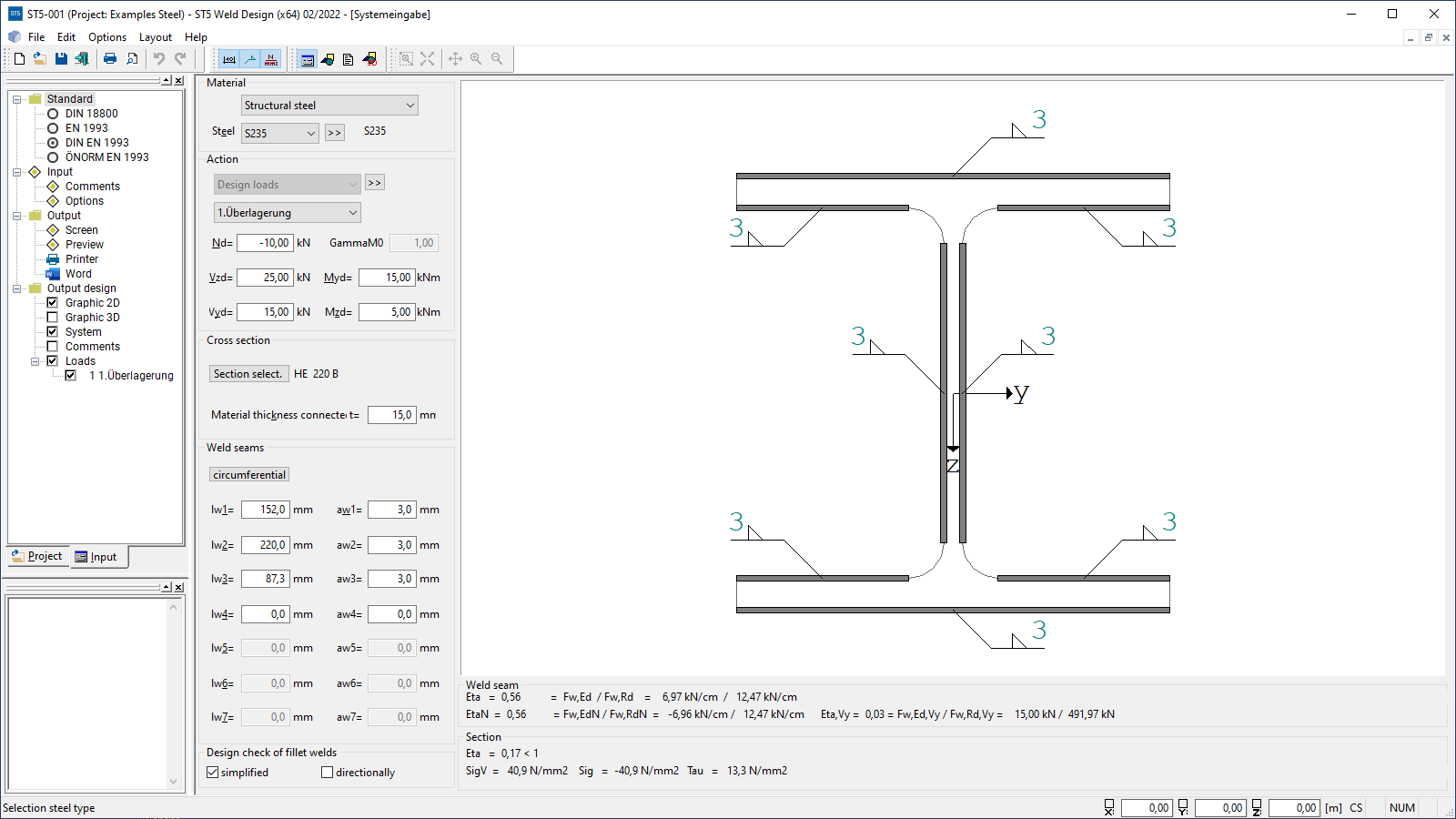

Weld seams:

- Depending on the selected section the most appropriate welding pattern is proposed

- The length and thickness of the weld seams is editable

- The suggested weld seam thickness is the smallest possible value that can be realised in construction

Loads

- Design internal forces from axial force, moment (My, Mz) and shear force (Vy, Vz)

- Multiple combinations of design internal forces can be entered

Design

Either the elastic or plastic cross-sectional resistance of the steel section is verified in accordance with EN 1993-1-1. For the verification of the weld seam, the user can select whether the simplified or directional method as per EN 1993-1-8 should be used.

Document file formats

- Word

- Printer

Output

- User-defined output scope

Export options

- DXF-file

Steel construction

- EN 1993

- DIN EN 1993

- ÖNORM EN 1993

- DIN 18800

News

FRILO launches version 2024-2 with powerful updates for structural analysis and design

Highlights include the optimised design of Schöck Isokörbe®, the advanced integration of DC foundation engineering programs into the FRILO environment and new RSX interfaces for detail verifications in steel construction.

Load determination for eight-floor perimeter block development with FRILO Building Model

Find out how the structural engineers at bauart Konstruktions GmbH determined the loads for an eight-floor perimeter block development in Frankfurt’s Europaviertel district using the GEO from FRILO.